What should I pay attention to when using the full-color LED display control card?

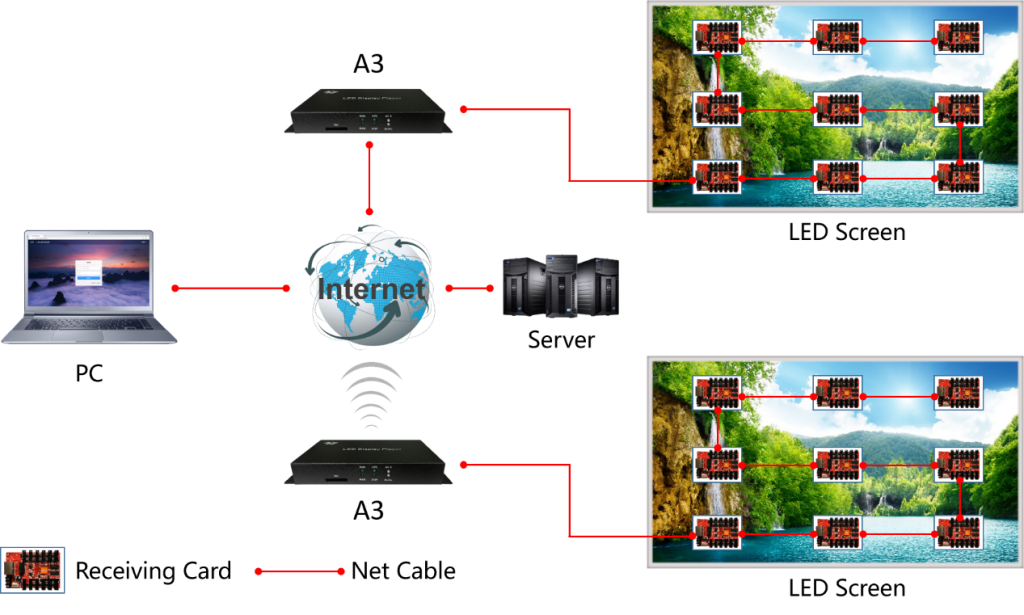

With the rapid development of the LED industry, the demand for the full-color LED display control card market is also increasing, and the wireless LED control card can well meet the market needs of customers for unified management and cluster transmission. As community publicity LED screens, vehicle screens, government projects, mobile, telecommunications, and bank door head screens, batch installation, easy management, and a state of no maintenance are the best choice for users. In order to avoid unnecessary losses when using the control card, the user should pay attention to the following points:

Seven precautions when using the full-color LED display control card

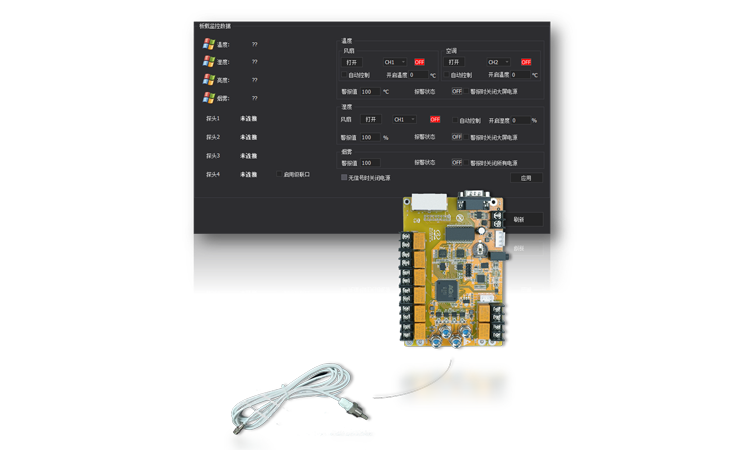

1. The full-color LED display control card should be used in a dry and relatively stable environment. Excessive temperature and humidity, as well as an environment with too much dust, are extremely unfavorable to the use of LED control cards.

2. It is strictly forbidden to plug and unplug the serial port without power failure, so as not to damage the serial port of the computer and the serial port of the full-color LED display control card due to improper operation.

3. It is strictly forbidden to adjust the input voltage of the full-color LED display control card when the system is working, so as not to damage the computer serial port and the serial port of the LED control card due to improper adjustment and excessive voltage. The normal working voltage of the control card is 5V. When adjusting the power supply voltage, you should remove the control card, and then use a multimeter to measure while adjusting. It is not advisable to adjust too high or too low at one time.

4. It is strictly forbidden to short-circuit the ground terminal of the control card with the LED display frame. Otherwise, once static electricity accumulates on the LED display frame, it will easily damage the serial port of the computer and the serial port of the control card, resulting in unstable communication. The display unit on the screen.

Therefore, for the LED outdoor display screen or when the communication distance is long, it is recommended that the user must use a serial port isolator to avoid the harsh environment of the computer serial port and the LED control card serial port due to ground loops, surges, induced lightning strikes, and hot plugging. Damage.

5. It is necessary to ensure the correct connection between the LED control card and the computer serial port, so as not to damage the control card serial port and the computer serial port due to incorrect input signals.

6. Do not connect the control card to the unit board. Directly lead to the switching power supply as much as possible, the voltage of the unit board is extremely unstable during the working process. It will cause the control card to be fast and slow, severely unable to communicate or the program runs out and needs to be repaired, especially the U disk control card, in the case of unstable voltage, it may not be able to read the disk or read the disk error.

7. Indoors, 16-scan unit boards should not be connected to the whole screen for debugging. Many indoor single-color or dual-color, or even full-color, and directly connected to the control card without debugging, may burn out the 4953 chip of the scan driver behind the unit board in a large area. For debugging, please connect only one unit board for debugging, unplug the power after debugging, and then connect the control card.

The full-color LED display control card is the core device of the product, and it is very necessary to master the common sense of using the above control card. BUYLEDCARD focuses on providing LED display control card, full-color LED display control systems, full-color LED display control card prices, etc.