What operating matters should the user pay attention to when using the LED display control card?

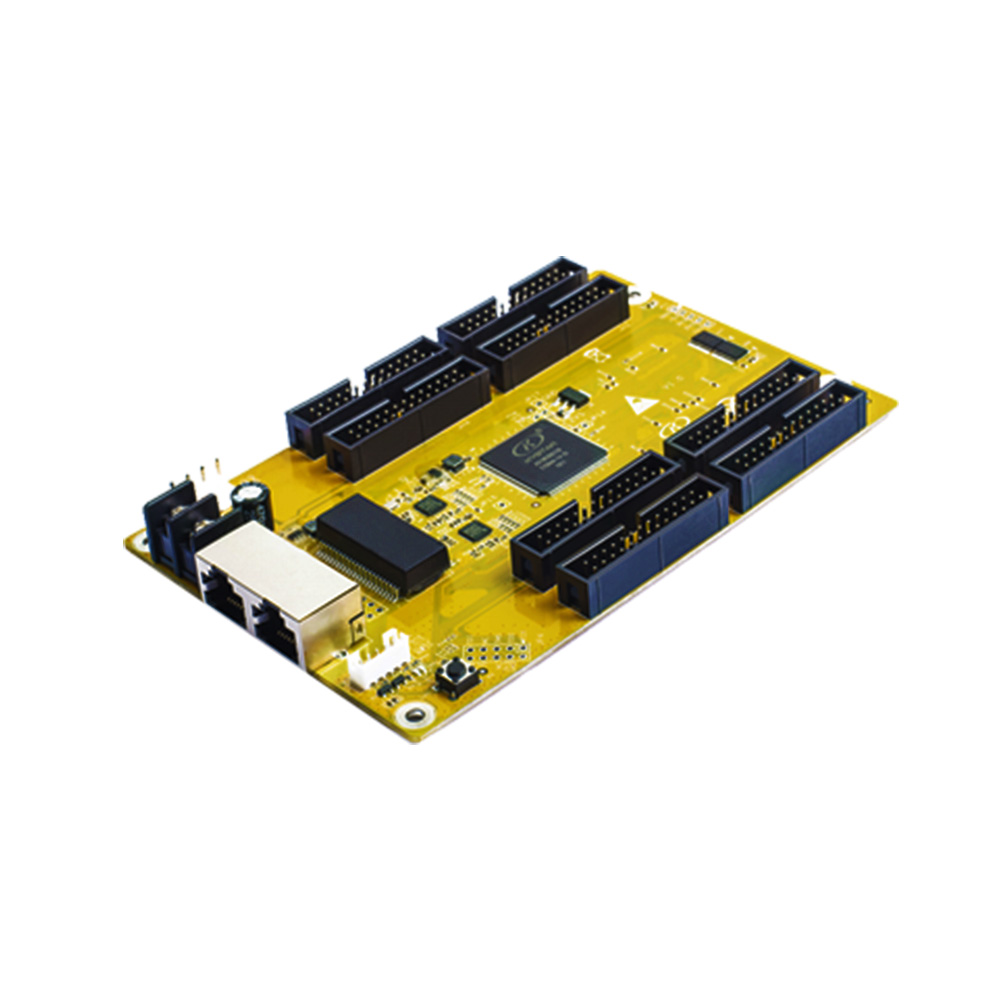

The LED control card, also known as the LED display control card, is an external device that converts the data of the LED display to the display through the PC. It is responsible for receiving the picture display information from the computer serial port. It is the core component of the LED graphic display. LED display control card can be divided into: single and double color control card, full color control card, 3G wireless control card. As the core part of the LED display, what matters should be paid attention to when it is used?

1. Please keep the LED display control card working in a dry, relatively stable environment. Excessive temperature, humidity, and dusty environment are extremely unfavorable to the control card.

2. It is strictly forbidden to plug and unplug the serial port without power failure, so as not to damage the computer serial port and the control card serial port due to improper operation.

3. It is strictly forbidden to adjust the input voltage of the control card when the system is working with electricity, to avoid damage to the computer serial port and the control card serial port due to improper adjustment or excessive voltage. The normal working voltage of the control card is 5V. When adjusting the power supply voltage, you should remove the control card and use a multimeter to measure and adjust slowly.

4. It is strictly forbidden to short-circuit the ground terminal of the LED display control card with the display frame, otherwise, once static electricity accumulates on the display frame, it is very easy to damage the computer serial port and the control card serial port, resulting in unstable communication, and the control card will be burned when the static electricity is serious. And the display unit on the screen.

Therefore, when the outdoor LED display screen or the communication distance is long, it is recommended that the user must use the serial port isolator to avoid the harsh environment of the computer serial port and the control card serial port due to the harsh environment such as ground loop, surge, induced lightning strike, and hot plugging.

5. The correct connection between the LED display control card and the computer serial port must be ensured to avoid damage to the control card serial port and the computer serial port due to incorrect input signals.

6. Do not connect the LED control card directly to the unit board. Directly lead to the switching power supply as much as possible, the voltage of the LED unit board is extremely unstable during the working process. It will cause the control card to be fast and slow, severely unable to communicate or program runaway and need to be repaired, especially the U disk control card, in the case of unstable voltage, it may not be able to read the disk or read the disk error.

7. Indoors, 16-scan LED unit boards should not be connected to the entire screen for debugging. Many indoor single-color or dual-color, or even full-color, directly connected to the control card to power on without debugging, may burn out the scan driver 4953 behind the unit board in a large area For the chip, only one LED unit board should be connected for debugging. After debugging, unplug the power supply and then connect the control card.

Things to pay attention to when using the LED display control card will make your LED display control card work better, in order to achieve the maximum use value of the LED display control card.