Description

Novastar CVT10 Pro Fiber Optic Converter product features

- Models include the CVT10 Pro-S (single-mode) and the CVT10 Pro-M (multi-mode).

- 2x optical ports with hot-swappable optical modules installed at the factory, bandwidth of each up to 10 Gbit/s

- 10x Gigabit Ethernet ports, the bandwidth of each up to 1 Gbit/s

- − Fiber in an Ethernet outIf the input device has 8 or 16 Ethernet ports, the first 8 Ethernet ports of the CVT10 Pro are available.

If the input device has 10 or 20 Ethernet ports, all the 10 Ethernet ports of the CVT10 Pro are available. If

Ethernet ports 9 and 10 are found unavailable, they will be available after upgrading in the future. - − Ethernet in and fiber outAll the 10 Ethernet ports of the CVT10 Pro are available.

- − Fiber in an Ethernet outIf the input device has 8 or 16 Ethernet ports, the first 8 Ethernet ports of the CVT10 Pro are available.

- 1x type-B USB control port

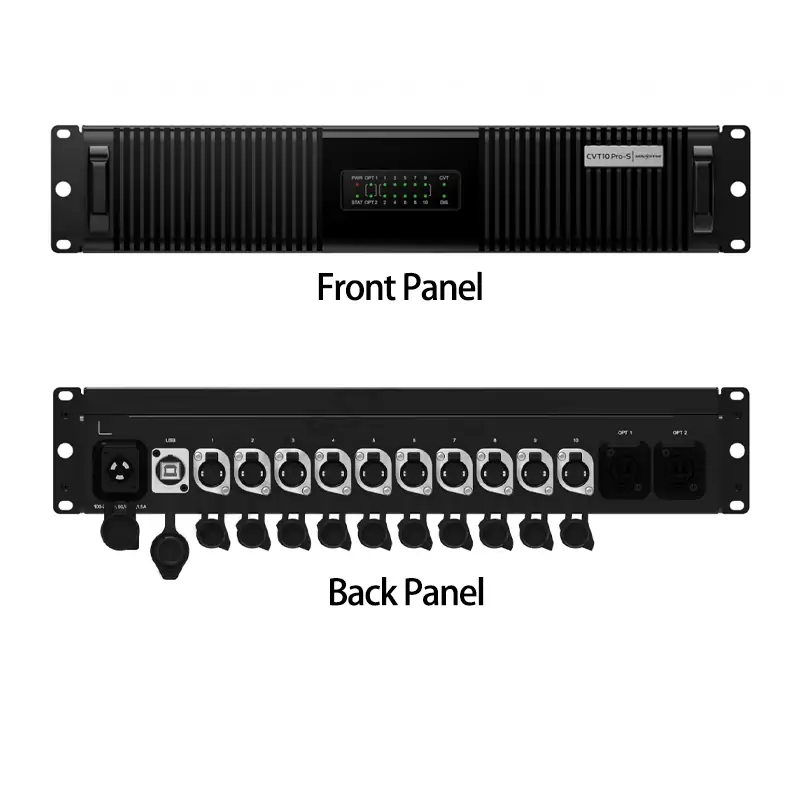

Appearance

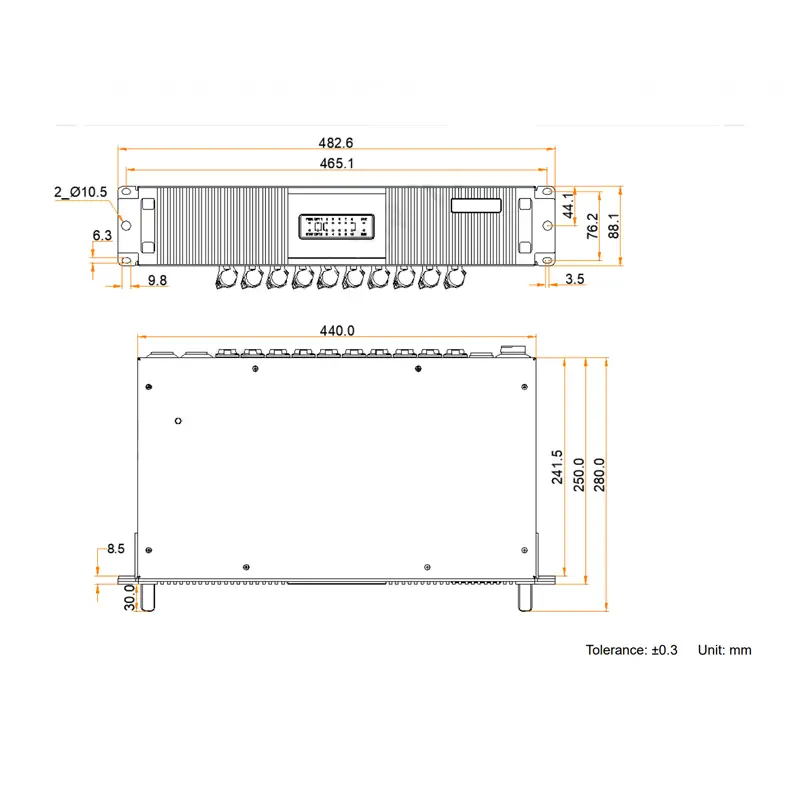

Dimensions

Notes and Cautions

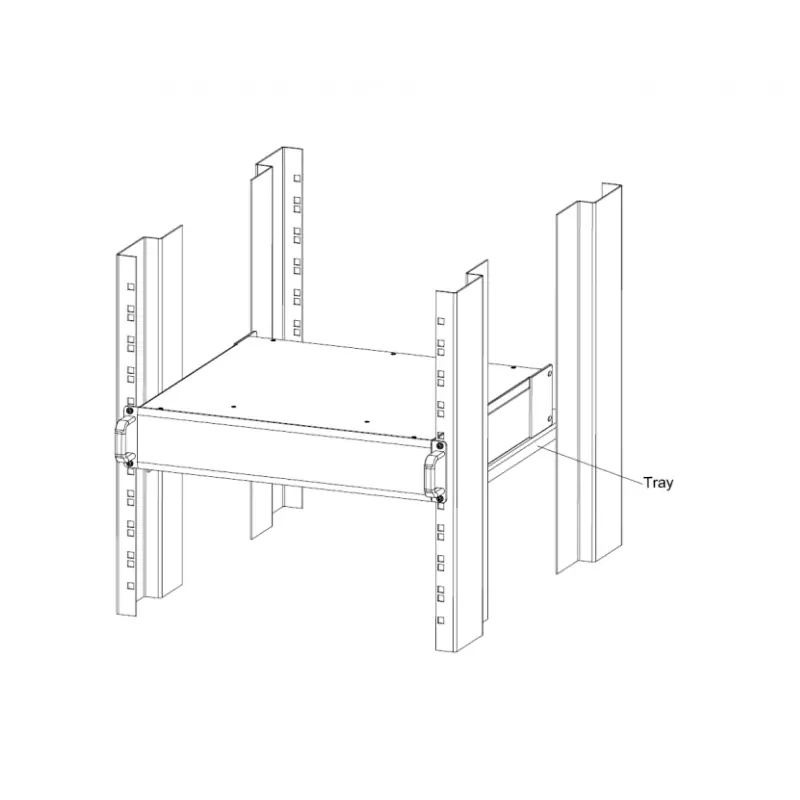

Notes for Installation

Caution: The equipment must be installed in a restricted access location.

Attention: L’équipement doit être installé dans un endroit à accès restreint.

When the product needs to be installed on the rack, 4 screws at least M5*12 should be used to fix it.

The rack for installation shall bear at least 25kg weight.

- Elevated Operating Ambient – If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than the room ambient. Therefore, consideration should be

given to installing the equipment in an environment compatible with the maximum ambient temperature (Tma)

specified by the manufacturer. - Reduced Air Flow – Installation of the equipment in a rack should be such that the amount of airflow required

for the safe operation of the equipment is not compromised. - Mechanical Loading – The mounting of the equipment in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading. - Circuit Overloading – Consideration should be given to the connection of the equipment to the supply circuit and

the effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be used when addressing this concern. - Reliable Earthing – Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit (e.g. use of power strips).